Continuous improvement is not merely a methodology; it's a mindset, a way of thinking and operating that revolves around the idea that every process, system, or product can be improved incrementally, no matter how well it is currently performing. This concept originated in post-World War II Japan, notably championed by companies like Toyota, which embraced Kaizen as a cornerstone of their success.

OVERVIEW

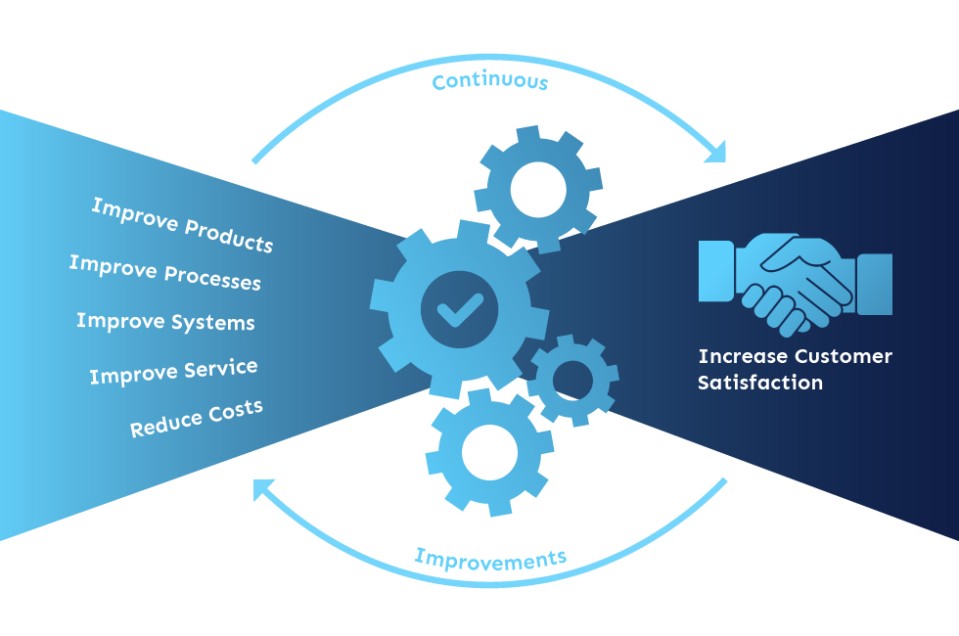

Continuous improvement is an ongoing effort to enhance processes, products, services, and outcomes within an organization. It involves systematically identifying opportunities for improvement, making incremental changes, and continually evaluating and refining existing practices to achieve better results.

The concept of continuous improvement is rooted in the philosophy of quality management and is widely applied in various fields, including business, manufacturing, healthcare, and software development. The primary goal of continuous improvement is to drive efficiency, effectiveness, and innovation by fostering a culture of learning, collaboration, and adaptation.

What Does Continuous Improvement Mean?

Continuous improvement, also known as continual improvement or continuous process improvement, refers to the ongoing effort to enhance processes, products, services, and outcomes within an organization. It involves identifying opportunities for improvement, making incremental changes, and continually evaluating and refining existing practices.

At its core, continuous improvement is about constantly striving for better results, efficiency, and effectiveness. It entails a mindset of never being satisfied with the status quo and always seeking ways to make things better. Continuous improvement is often driven by data and evidence, fostering a culture of learning, adaptation, and innovation.

Overall, continuous improvement embodies the philosophy of striving for excellence, embracing change, and constantly evolving to meet the ever-changing needs and expectations of customers, stakeholders, and the business environment.

Key Principles of Continuous Improvement

Continuous improvement is guided by several key principles:

-

Iterative Approach:

Continuous improvement is a cyclical process that involves regularly assessing current performance, setting improvement goals, implementing changes, and measuring the impact of those changes. This iterative approach ensures that improvements are ongoing and sustained.

-

Data-Driven Decision Making:

Continuous improvement relies on collecting and analyzing relevant data to identify areas for improvement and to measure the effectiveness of implemented changes. Data provides insights into existing processes, highlights bottlenecks or inefficiencies, and guides decision-making.

-

Employee Involvement:

Organizations encourage employees at all levels to actively participate in the continuous improvement process. Since frontline workers often have valuable insights into operational challenges, their involvement fosters a sense of ownership and empowerment, leading to better ideas and solutions.

-

Kaizen Philosophy:

Kaizen, a Japanese term meaning "change for the better," is closely associated with continuous improvement. It emphasizes the pursuit of small, incremental changes rather than radical transformations. Kaizen encourages everyone in the organization to seek improvement opportunities and contribute to the collective progress.

-

Standardization and Documentation:

Continuous improvement involves documenting processes, procedures, and best practices. Standardizing workflows and making them easily accessible to employees allows for consistent execution and provides a baseline for evaluating improvements.

Benefits of Continuous Improvement

The benefits of continuous improvement include increased productivity, enhanced quality, reduced costs, improved customer satisfaction, greater employee engagement, and a culture of innovation. By embracing continuous improvement, organizations can adapt to changing circumstances, stay competitive, and drive long-term success.

Where to Implement Continuous Improvement

Continuous improvement can be implemented in various areas within an organization, including:

- Processes and Workflows: Streamlining operations, reducing waste, and improving productivity.

- Product Development and Innovation: Meeting evolving customer needs and staying ahead of the competition.

- Quality Management: Addressing quality issues, reducing defects, and improving overall quality performance.

- Customer Service: Enhancing the customer experience and delivering efficient service.

- Supply Chain and Logistics: Optimizing supply chain operations for efficiency and cost reduction.

- Employee Training and Development: Empowering employees with the skills and knowledge needed to identify improvement opportunities.

- Information Technology: Enhancing software development and IT processes.

- Safety and Environmental Practices: Promoting safety and sustainability.

Continuous improvement is not limited to these areas and can be applied throughout an organization.

What are continuous improvement tools?

There are several tools and methodologies that organizations commonly use to facilitate and support continuous improvement initiatives. These tools help in identifying improvement opportunities, analyzing data, solving problems, and implementing changes. Here are some widely used tools for continuous improvement:

-

Plan-Do-Check-Act (PDCA) Cycle:

The PDCA cycle, also known as the Deming cycle or the Shewhart cycle, is a fundamental tool for continuous improvement. It involves four stages: Plan (identify the problem and plan the improvement), Do (implement the planned changes on a small scale), Check (evaluate the results and collect data), and Act (standardize the successful changes and implement them on a larger scale). The PDCA cycle promotes iterative and ongoing improvement efforts.

-

Kaizen Events:

Kaizen is a Japanese term meaning "change for the better" or "continuous improvement." Kaizen events, also known as Kaizen blitz or rapid improvement events, are focused improvement workshops conducted over a short period, typically a few days. They bring together a cross-functional team to identify and address specific problems or improvement opportunities using various tools and techniques.

-

Lean Manufacturing/Lean Six Sigma:

Lean principles aim to eliminate waste, reduce non-value-added activities, and optimize processes. Lean tools such as Value Stream Mapping (VSM), 5S (Sort, Set in Order, Shine, Standardize, Sustain), Kanban, and Just-in-Time (JIT) help streamline operations, improve flow, and enhance efficiency. Six Sigma, often combined with Lean, focuses on reducing process variation and defects through statistical analysis and problem-solving methodologies.

-

Root Cause Analysis (RCA):

Root cause analysis is a systematic process used to identify the underlying causes of problems or defects. Techniques like the 5 Whys, Fishbone Diagram (Ishikawa Diagram), and Fault Tree Analysis help to dig deep into the root causes and facilitate effective problem-solving and corrective actions.

-

Statistical Process Control (SPC):

SPC involves monitoring and controlling a process using statistical techniques to ensure it remains in a state of control and produces consistent, high-quality output. Control charts, Pareto charts, and process capability analysis are some of the tools used in SPC to monitor variation, identify trends, and make data-driven decisions for process improvement.

-

Standard Work:

Standard work refers to documenting and establishing the best-known method for performing a task or process. It provides a baseline for consistency, efficiency, and continuous improvement. Standard operating procedures (SOPs), work instructions, and visual aids like Standard Work Combination Sheets (SWCS) and Standardized Work Charts (SWCs) help ensure consistent and reliable processes.

-

Quality Circles:

Quality circles are small groups of employees who meet regularly to identify, analyze, and solve work-related problems. They encourage employee participation, engagement, and ownership in continuous improvement initiatives.

-

Gemba Walks:

Gemba walks involve going to the "gemba," which is the actual place where work is performed, to observe and understand the process firsthand. It encourages leaders and managers to engage with employees, identify improvement opportunities, and gather insights for continuous improvement.

These are just a few examples of tools used in continuous improvement. Depending on the specific needs and context of an organization, different tools and techniques may be utilized to drive improvement efforts. It is important to select and apply the appropriate tools based on the problem or opportunity at hand to facilitate effective and sustainable improvements.

CONCLUSION

Continuous improvement is a dynamic and vital concept that empowers organizations to evolve, innovate, and thrive. By embracing a culture of ongoing learning and adaptation, businesses can unlock their potential for excellence and long-term success. The key lies in the systematic identification of opportunities, data-driven decision-making, and active employee involvement, all guided by a commitment to achieving better results. In the ever-changing landscape of modern business, continuous improvement is not just a strategy; it's a fundamental mindset that drives progress and excellence.

QUESTION:

What are your thoughts on the subject above? Feel free to post a comment or start a discussion.

TAGS: Continuous Improvement, Excellence, Process Optimization, Performance Enhancement, Kaizen, Lean Management, Quality Improvement, Operational Excellence, Business Growth, Organizational Development, Productivity, Problem Solving, Best Practices, Leadership, Teamwork, Efficiency, Change Management, Root Cause Analysis, Data Analysis, Continuous Learning, Lean Six Sigma, Innovation, Customer Satisfaction, Employee Engagement, Goal Setting, Benchmarking, Improvement Metrics, Leadership Development, Training and Development, Performance Metrics.

Leave A Comment