Imagine a business world where quality is not just a goal but a way of life—a perpetual journey of improvement that infiltrates every aspect of an organization. This captivating management philosophy is none other than Total Quality Management (TQM), a transformative approach designed to revolutionize the quality of products, services, and processes within your company. By embracing continuous, organizations can view each step as a problem-solving process—systematically exploring and analyzing operations. The aim is to identify the root causes of any issues, implementing targeted corrective actions to eliminate shortcomings and safeguard against their recurrence.

OVERVIEW

So, what exactly is TQM and how can it propel your organization to new heights of success?

What is Total Quality Management?

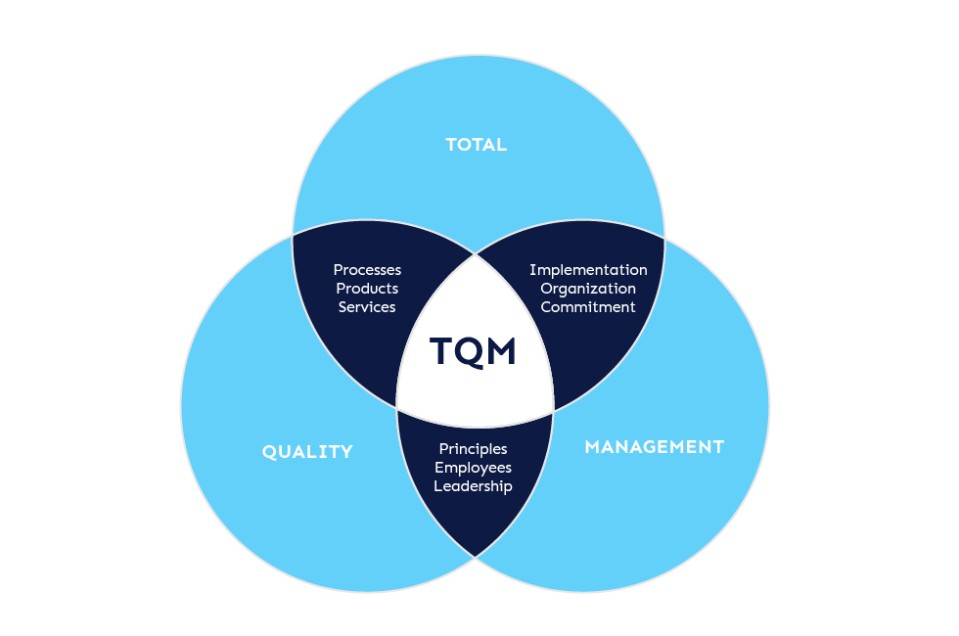

TQM is more than a mere buzzword; it's a comprehensive system that permeates every level and function of your business. At its core lies the unwavering commitment and involvement of all employees, making it a truly collaborative endeavor. With TQM, the entire organization rallies under the banner of quality improvement, recognizing that the pursuit of excellence is an ongoing problem-solving process.

The essence of TQM lies in the belief that meeting customer requirements is the ultimate objective of any organization. By embracing continuous improvement, TQM empowers your team to identify and address areas for enhancement across all processes. As these improvements take root, they ripple through the entire organization, directly impacting the quality of your products or services.

But TQM doesn't stop there—it extends its influence beyond your internal operations and into the competitive market landscape. By embracing a series of organizational changes and leveraging powerful tools, TQM unlocks the full potential of your processes and products. The result? Enhanced efficiency, superior performance, heightened flexibility, and, ultimately, a significant competitive advantage that sets your business apart.

To fully embrace TQM, both management and employees must undergo a paradigm shift in their thinking and behavior. This fundamental transformation requires a collaborative effort, as well as structural and organizational adjustments. At the heart of TQM lies strategic control over quality by top management, complemented by the promotion of a quality-oriented mindset among employees. Together, these elements foster a proactive approach to preventing quality-related issues in your products, processes, and operations.

TQM, also known as Total Quality Control, is a dynamic management and implementation philosophy that harnesses the human and material resources of your organization to achieve defined goals in the most effective manner. By tapping into the hidden reserves and capabilities of every employee, TQM continuously improves the quality of your processes, products, and services. With a satisfied customer as the ultimate goal, TQM not only elevates your organization's reputation but also drives down costs, positioning you for long-term success.

Enter Kaizen—an evocative term originating from Japan, which literally means "change for the better." At its core, Kaizen embodies the principle of continuous improvement—a holistic, long-term process seamlessly integrated at every level of your company. With Kaizen, your organization unlocks the immense power of knowledge, experience, and skills residing within your talented workforce. This wealth of "hidden" knowledge already exists within your organization; it simply requires the removal of obstacles for it to circulate freely among your colleagues.

Building upon this foundation, continuous improvement rests upon two pivotal pillars. First, systematic selection and repetition of improvements, driven by scientific and professional knowledge, ensure that your organization is constantly advancing. Second, the relentless pursuit of waste elimination—activities that fail to add value—becomes the driving force behind your improvement initiatives.

What are the principles of TQM?

At the heart of Total Quality Management (TQM) lie four powerful principles, each serving as a guiding light on the path to organizational excellence. Let's delve into these principles and uncover how they can revolutionize your organization.

TQM begins with the fundamental principle that an organization thrives when all its parts work together towards shared goals. Recognizing that every individual, at every level of the organization, and every activity impacts and is influenced by others, TQM fosters a harmonious synergy that propels your organization forward. Ultimately, the driving force behind your organization's existence and operation is the satisfaction of customer requirements and needs.

- The first principle of TQM is Customer Focus. Placing utmost importance on understanding and meeting customer needs and expectations, TQM positions the customer at the core of all activities. By actively listening to customers, conducting market research, and continuously enhancing customer experiences, organizations can deliver products and services that genuinely satisfy their customers.

- Next, TQM emphasizes Continuous Improvement—a culture of perpetual advancement. Through rigorous assessment and refinement of processes, products, and services, organizations embark on a relentless pursuit of excellence. By utilizing quality tools and techniques, they identify areas for improvement, implement changes, and measure the results. This commitment to continuous improvement enables organizations to stay ahead of the competition and meet ever-evolving customer demands.

- TQM also recognizes the vital role of Employee Empowerment and Involvement. Employees are considered valuable assets, integral to the organization's success. TQM fosters teamwork, collaboration, and active participation in decision-making processes. By empowering employees and nurturing a culture of ownership, organizations tap into the knowledge, skills, and creativity of their workforce to drive quality improvement initiatives.

-

Process Orientation is another key principle of TQM. It emphasizes understanding and managing processes effectively. Through process mapping, analysis, and identification of areas for improvement, organizations eliminate waste, reduce errors, and optimize efficiency. This process-oriented approach ensures that work is carried out systematically, leading to consistent and high-quality outcomes.

-

Data-Driven Decision Making is a cornerstone of TQM. It stresses the use of data and facts to inform decision-making. Organizations collect and analyze data related to quality performance, customer feedback, and process metrics. This data-driven approach enables informed decision-making, identifies areas for improvement, and ensures changes are based on objective evidence rather than assumptions.

- TQM places importance on forging strong Supplier Relationships. Collaborating closely with suppliers to ensure the quality of incoming materials and services, organizations foster mutual trust, collaboration, and continuous improvement. By creating a seamless supply chain, they deliver high-quality products or services to customers.

- Lastly, Leadership Commitment is paramount in TQM. Strong leaders set the vision, establish quality policies, and cultivate a culture that fosters a commitment to quality and continuous improvement. They provide the necessary resources, training, and support to drive TQM initiatives throughout the organization.

By embracing these principles, you establish a solid foundation for a thriving organization—one that excels in quality, customer satisfaction, and continuous improvement. TQM empowers you to make data-driven decisions, forge strong supplier relationships, and nurture a culture of leadership commitment. Embarking on a transformative journey, you elevate your organization to new heights of excellence, where you outshine the competition and become a beacon of success.

What are the Characteristics of Total Quality Management?

Total Quality Management (TQM) is not just a concept; it's a set of characteristics that define its implementation and practice within organizations. These characteristics form the very essence of TQM, creating a framework for achieving excellence. Let's delve into the essential characteristics of TQM that set the stage for organizational success.

-

First and foremost, TQM is strategically oriented. It aligns with an organization's vision, mission, and overall strategy. Quality is not an afterthought but an integral part of the organization's goals and objectives. TQM ensures that quality is woven into the fabric of the organization, driving business success and creating a competitive edge.

-

Customer focus is another vital characteristic of TQM. It places a strong emphasis on understanding and meeting the needs and expectations of both internal and external customers. TQM organizations prioritize listening to customers, gathering feedback, and continuously improving products, services, and processes to enhance customer experiences. By putting the customer at the heart of their operations, organizations can build strong relationships and loyalty.

-

TQM requires a deep-rooted commitment to quality from every employee. It goes beyond mere compliance and instills a mindset of continuous improvement. TQM organizations foster a culture where each employee takes personal ownership and accountability for delivering high-quality outcomes. This commitment to quality permeates every level of the organization, creating a shared responsibility for excellence.

-

An analytical approach to decision-making and problem-solving is inherent in TQM. It relies on data and facts to drive informed decisions and solve problems systematically. TQM organizations utilize various quality tools, techniques, and statistical methods to benchmark performance, monitor effectiveness, and drive continuous improvement. This analytical mindset ensures that decisions are based on evidence and leads to more effective outcomes.

-

TQM is not a short-term fix; it requires a long-term orientation and commitment. It represents a fundamental shift in how organizations conduct business. TQM organizations understand that building a culture of quality excellence takes time and perseverance. They embrace a long-term perspective, nurturing a new organizational culture that prioritizes quality, continuous improvement, and customer satisfaction.

-

Teamwork plays a crucial role in TQM. It fosters collaboration, cooperation, and communication among employees and teams. TQM organizations promote a culture where individuals work together, share knowledge and expertise, and support one another to achieve common quality goals. By harnessing the power of teamwork, organizations can leverage the collective intelligence and skills of their employees.

-

Continuous improvement lies at the core of TQM. It is a never-ending journey of seeking opportunities for enhancement. TQM organizations encourage employees to proactively identify areas for improvement, implement changes, and monitor the results. This commitment to continuous improvement ensures that organizations stay competitive, adapt to changing market needs, and deliver increasing value to customers.

-

Education and training are vital in developing the knowledge and skills necessary for quality excellence. TQM organizations invest in employee development, providing the necessary training and resources to understand and implement TQM principles effectively. By fostering a culture of continuous learning and improvement, organizations empower their employees to excel in their roles and contribute to the overall success of the organization.

-

TQM emphasizes the unity of purpose. It aligns individual and team goals with the overall quality objectives of the organization. TQM organizations ensure that everyone understands and shares the same commitment to quality excellence. This unity of purpose creates a sense of cohesion and synergy, driving the organization towards its quality goals.

-

Lastly, TQM actively involves and empowers employees at all levels. It recognizes that involving employees in decision-making and problem-solving processes increases the likelihood of making good decisions and implementing effective solutions. TQM organizations value employee contributions, encouraging them to share their ideas, expertise, and creativity. By empowering employees, organizations tap into their full potential, driving innovation and continuous improvement.

By embracing these characteristics, organizations can establish a TQM culture that drives continuous improvement, customer satisfaction, and organizational excellence. TQM becomes ingrained in the organization's DNA, shaping its operations, decision-making processes, and overall success. Embrace the power of TQM, and unlock the full potential of your organization.

What is Total Quality Management Pyramid?

The Quality Management Pyramid is more than just a visual representation; it's a roadmap to excellence within organizations. This framework illustrates the hierarchy of quality management activities, guiding organizations on their journey to improved quality and customer satisfaction. Let's explore the three levels of the pyramid and uncover the secrets to effective quality management.

At the foundation level, we find the core principles and concepts that lay the groundwork for success. This level sets the direction and culture for quality management within the organization. It encompasses essential elements such as leadership commitment, customer focus, employee involvement, and process orientation. By embracing these foundational pillars, organizations create a solid base for their quality management practices.

Moving up the pyramid, we reach the middle level, which represents the operational aspects of quality management. Here, organizations focus on implementing practical actions to monitor, control, and improve processes and products. Quality planning, process control, data analysis, measurement, and corrective and preventive actions take center stage. This level ensures that quality objectives are translated into tangible actions and that processes are effectively managed to achieve the desired quality outcomes.

Finally, at the top level of the pyramid, we encounter the strategic aspect of quality management. This level involves higher-level decision-making and strategic planning to align quality management with the organization's overall objectives. Here, organizations set quality goals, define quality policies, establish performance indicators, conduct management reviews, and foster continuous improvement. The top-level ensures that quality management is seamlessly integrated into the organization's overarching strategy, contributing to long-term success.

The Quality Management Pyramid offers a holistic view of quality management, recognizing the interconnectedness of its different elements. It serves as a reminder that effective quality management requires a comprehensive approach, starting from foundational principles, extending to operational implementation, and aligning with strategic goals. By following the roadmap provided by the Quality Management Pyramid, organizations can navigate their way to improved quality, customer satisfaction, and organizational excellence.

What Makes Total Quality Management Relevant and Important in Today's Business Landscape

Total Quality Management (TQM) emerges as a cornerstone of success in today's dynamic and ever-evolving business landscape. Its relevance and importance stem from the multitude of benefits it offers organizations across sectors and industries.

One of the primary reasons TQM is relevant today is its ability to create a culture of continuous improvement. TQM focuses on enhancing processes, products, and services through a systematic approach that encourages ongoing evaluation and refinement. In an era where competition is fierce, organizations that embrace TQM can adapt to changing market demands, identify areas for improvement, and stay ahead of their competitors.

Moreover, TQM recognizes the significance of the human element in organizational success. It goes beyond merely optimizing processes and involves engaging employees at every level. By nurturing an inclusive work environment that empowers individuals, encourages collaboration, and values their ideas and expertise, TQM ignites a flame within the workforce. Engaged employees become more committed, innovative, and proactive, leading to enhanced productivity and improved outcomes that epitomize excellence. TQM recognizes that people are the driving force behind any organization, and their involvement and satisfaction directly impact the quality of products and services delivered.

In addition to its impact on organizational culture, TQM stands as a guardian angel in an unpredictable world, mitigating risks and safeguarding organizations from potential pitfalls. By implementing foolproof quality control processes, organizations proactively address quality concerns and ensure that products and services consistently meet or exceed customer expectations. This approach not only minimizes the likelihood of defects or failures but also helps organizations adhere to regulations and standards, avoiding legal liabilities and reputational damage.

By adopting TQM principles, organizations can achieve numerous benefits, including increased customer satisfaction, improved operational efficiency, reduced costs, enhanced brand reputation, and sustained business growth. TQM acts as a guiding philosophy that permeates every aspect of an organization, fostering a culture of excellence and continuous improvement.

How does Total Quality Management helps organizations grow?

Total Quality Management (TQM) plays a crucial role in facilitating the growth of organizations in several ways:

-

Improved Customer Satisfaction: TQM focuses on understanding and meeting customer needs and expectations. By consistently delivering high-quality products and services, organizations can enhance customer satisfaction. Satisfied customers are more likely to become repeat customers, provide positive reviews, and recommend the company to others. This leads to increased customer retention, expanded market share, and accelerated business growth.

-

Enhanced Operational Efficiency: TQM emphasizes the identification and elimination of waste, inefficiencies, and defects in organizational processes. Through continuous improvement efforts, organizations can streamline their operations, optimize workflows, and enhance overall efficiency. This results in improved productivity, reduced costs, and the ability to allocate resources effectively. Increased operational efficiency enables organizations to scale their operations and handle growing demands efficiently.

-

Employee Engagement and Empowerment: TQM promotes a culture of employee involvement, empowerment, and continuous learning. Engaged employees are more motivated, innovative, and committed to the success of the organization. By providing employees with the tools, training, and autonomy to contribute to quality improvement initiatives, organizations tap into their full potential. Engaged and empowered employees become valuable assets who drive growth through their dedication, creativity, and contributions.

-

Strengthened Supplier Relationships: TQM extends beyond the organization's boundaries to include suppliers and other external stakeholders. By collaborating closely with suppliers and ensuring their adherence to quality standards, organizations build strong and reliable supplier relationships. These relationships contribute to the overall quality of the end product or service. Reliable suppliers enable organizations to meet customer demands promptly, maintain consistent quality, and support business growth.

-

Continuous Improvement and Innovation: TQM fosters a culture of continuous improvement and innovation within organizations. Through ongoing evaluation, analysis of data, and feedback from customers and employees, organizations identify areas for enhancement. By embracing a mindset of continuous improvement, organizations can adapt to changing market dynamics, identify emerging opportunities, and stay ahead of competitors. Continuous improvement and innovation are key drivers of business growth and long-term sustainability.

-

Positive Reputation and Brand Image: TQM helps build a positive organizational reputation and brand image. When customers perceive a company as consistently delivering high-quality products and services, it enhances their trust and confidence. A positive reputation and brand image attract new customers, enhance market share, and differentiate the organization from competitors. A strong reputation is a valuable asset that contributes to business growth and success.

By implementing Total Quality Management, organizations strive to enhance customer satisfaction, reduce waste and defects, improve operational efficiency, increase employee morale, and achieve long-term success. TQM is not a one-time initiative but an ongoing process that requires sustained effort and commitment from all levels of the organization.

Why does Total Quality Management fail?

While Total Quality Management (TQM) can bring significant benefits to organizations, there are several reasons why it may fail to deliver the desired outcomes. Some common factors that can contribute to the failure of TQM implementation include:

-

Lack of Leadership Commitment: TQM requires strong leadership commitment and support at all levels of the organization. If top management fails to prioritize and actively engage in TQM initiatives, it can lead to a lack of direction, inadequate resource allocation, and a lack of motivation among employees.

-

Inadequate Employee Involvement: TQM relies on active employee participation and empowerment. If employees are not adequately involved or do not understand the principles and benefits of TQM, the implementation may lack buy-in and enthusiasm. Without employee involvement, TQM initiatives may encounter resistance or fail to generate sustainable improvements.

-

Poor Communication and Training: Effective communication is essential for successful TQM implementation. If there is a lack of clear and consistent communication about TQM goals, processes, and expectations, employees may not fully understand their roles or the benefits of TQM. Insufficient training and development programs can also hinder employees' ability to implement TQM practices effectively.

-

Inadequate Measurement and Feedback Systems: TQM relies on data-driven decision-making and continuous improvement. If organizations do not establish effective measurement systems or fail to collect and analyze relevant data, they may lack the insights necessary to identify improvement opportunities and measure progress accurately. Without proper feedback mechanisms, organizations may struggle to make informed adjustments and sustain TQM efforts.

-

Overemphasis on Tools and Techniques: TQM is not just about implementing tools and techniques but requires a holistic approach. If organizations focus solely on adopting TQM tools without addressing cultural, behavioral, and systemic issues, it can lead to a superficial implementation that fails to bring about lasting change.

-

Lack of Integration with Business Strategy: TQM should align with the organization's overall business strategy and objectives. If TQM initiatives are implemented in isolation from the strategic direction of the organization, they may lack relevance and fail to gain support from key stakeholders.

-

Resistance to Change: Implementing TQM often requires significant changes in processes, roles, and behaviors. Resistance to change from employees or organizational inertia can impede the successful implementation of TQM initiatives. Without addressing resistance and providing support during the transition, TQM efforts may struggle to gain traction.

-

Unrealistic Expectations and Short-term Focus: TQM is a long-term approach to quality improvement. If organizations have unrealistic expectations for immediate results or focus solely on short-term gains, they may abandon TQM initiatives prematurely or fail to invest sufficient time and resources for sustainable change.

It's important to note that while TQM can face challenges and potential failure, addressing these factors through effective planning, communication, leadership, and sustained commitment can increase the chances of successful implementation and reap the benefits of TQM.

Should Total Quality Management be Measured?

Measuring TQM is crucial for assessing effectiveness, monitoring performance, identifying improvement opportunities, enhancing decision-making, demonstrating accountability, driving continuous improvement, and benchmarking against industry standards. It provides a framework for organizations to track their progress, align their efforts, and continuously strive for excellence in quality management.

Measuring Total Quality Management (TQM) is essential for several reasons:

-

Assessing Effectiveness: Measuring TQM allows organizations to evaluate the effectiveness of their quality management practices and initiatives. It provides insights into how well TQM principles and processes are being implemented and whether they are delivering the desired outcomes. Measuring TQM helps organizations identify strengths, weaknesses, and areas for improvement in their quality management systems.

-

Monitoring Performance: TQM measurement provides a means to monitor performance against established quality objectives, targets, and benchmarks. It allows organizations to track progress over time and compare their performance to industry standards or competitors. Monitoring TQM performance helps organizations identify deviations, trends, and areas requiring attention to ensure continuous improvement.

-

Identifying Improvement Opportunities: Measuring TQM helps organizations identify areas for improvement and potential quality gaps. By analyzing performance metrics, organizations can pinpoint specific processes, systems, or areas where quality improvements are needed. It provides a basis for making data-driven decisions and prioritizing improvement efforts to enhance overall quality and operational effectiveness.

-

Enhancing Decision-making: TQM measurement provides meaningful data and information that supports informed decision-making. By having access to accurate and timely quality-related data, organizations can make better decisions related to process improvements, resource allocation, customer satisfaction strategies, supplier management, and risk mitigation. TQM measurement enables organizations to make decisions based on objective evidence rather than assumptions or guesswork.

-

Demonstrating Accountability: Measuring TQM enables organizations to demonstrate their accountability to stakeholders, including customers, employees, suppliers, and regulatory bodies. It provides evidence of the organization's commitment to quality and its ability to meet customer expectations. By transparently measuring and reporting on TQM performance, organizations can build trust and credibility with stakeholders, which is vital for long-term success.

-

Driving Continuous Improvement: TQM measurement is closely tied to the principle of continuous improvement. By measuring TQM, organizations can identify opportunities for ongoing enhancements, set new targets, and track the impact of improvement initiatives. It creates a feedback loop that encourages the organization to continuously strive for higher levels of quality and performance.

-

Benchmarking and Learning: Measuring TQM allows organizations to benchmark their performance against industry standards, best practices, or competitors. It provides insights into where the organization stands relative to others in terms of quality and can reveal opportunities for learning and adopting innovative practices. Benchmarking helps organizations identify areas for improvement and adopt proven strategies to enhance their TQM practices.

How can Total Quality Management be measured?

Total Quality Management (TQM) can be measured using various quantitative and qualitative metrics. These measurements provide insights into the effectiveness of TQM implementation and the organization's overall quality performance.

Here are some commonly used methods and metrics for measuring TQM:

-

Customer Satisfaction: Customer satisfaction surveys, feedback mechanisms, and Net Promoter Score (NPS) can measure the level of satisfaction customers have with the organization's products or services. This metric helps gauge the effectiveness of TQM in meeting customer expectations and delivering high-quality experiences.

-

Defect Rate: The defect rate measures the number or percentage of defects or non-conformities in products or services. It indicates the level of quality achieved and the effectiveness of TQM processes in preventing and addressing defects.

-

Process Efficiency and Cycle Time: Metrics such as cycle time, lead time, and process efficiency ratios (e.g., productivity, utilization) can assess the effectiveness of TQM in improving operational processes and reducing waste. It measures the time taken to complete a process or deliver a product/service, helping identify areas for improvement.

-

Cost of Quality (COQ): COQ measures the costs incurred due to poor quality, including prevention costs, appraisal costs, internal failure costs, and external failure costs. By tracking COQ, organizations can evaluate the effectiveness of TQM in reducing costs associated with quality issues and rework.

-

Employee Engagement: Surveys, feedback mechanisms, and employee satisfaction metrics can assess the level of employee engagement and their perception of TQM implementation. Engaged employees are more likely to contribute to quality improvement efforts and align with TQM principles.

-

Supplier Performance: Metrics related to supplier quality, such as on-time delivery, defect rate, and adherence to specifications, can measure the effectiveness of TQM in managing supplier relationships and ensuring high-quality inputs.

-

Continuous Improvement Initiatives: Tracking the number of implemented improvement projects, cost savings or revenue generated from improvement initiatives, and the effectiveness of corrective and preventive actions can indicate the success of TQM in driving continuous improvement.

-

Audit Results: Regular quality audits can assess adherence to TQM processes and identify areas of non-compliance or improvement. Audit findings and their resolution rates can provide insights into the effectiveness of TQM implementation.

-

Regulatory Compliance: Compliance with industry standards, regulations, and certifications (e.g., ISO 9001) can be measured to assess the effectiveness of TQM in meeting regulatory requirements and maintaining quality standards.

-

Benchmarking: Comparing the organization's performance against industry benchmarks, best practices, or competitors' quality metrics can provide insights into the effectiveness of TQM and identify areas for improvement.

It's important to establish a balanced set of metrics that align with organizational goals, customer requirements, and the principles of TQM. The selected metrics should be regularly tracked, analyzed, and used to drive continuous improvement and strategic decision-making.

Which Total Quality Management System?

There are several Total Quality Management (TQM) systems or frameworks that organizations can adopt to implement quality management practices.

Here are a few widely recognized TQM systems:

-

ISO 9000: The ISO 9000 series is a set of international standards developed by the International Organization for Standardization (ISO). These standards provide guidelines for implementing a quality management system that focuses on customer satisfaction, process efficiency, and continuous improvement. ISO 9001 certification is a globally recognized standard that demonstrates an organization's commitment to quality management.

-

Six Sigma: Six Sigma is a data-driven methodology that aims to minimize defects and variation in processes to achieve near-perfect quality. It involves defining, measuring, analyzing, improving, and controlling processes to reduce errors and waste. Six Sigma uses statistical tools and techniques to drive process improvement and achieve higher levels of quality.

-

Lean Manufacturing: Lean manufacturing, also known as Lean or Lean Production, is a systematic approach to process improvement that emphasizes waste reduction, improved efficiency, and value creation. It focuses on eliminating non-value-added activities, optimizing flow, and maximizing customer value. Lean principles, such as Just-in-Time (JIT) production and Continuous Flow, aim to streamline processes and improve overall quality.

-

Total Quality Control (TQC): Total Quality Control is a Japanese approach to TQM that emphasizes employee involvement, teamwork, and continuous improvement. TQC focuses on defect prevention rather than detection and encourages the use of quality circles, employee empowerment, and statistical process control to drive quality improvements.

-

Baldrige Excellence Framework: The Baldrige Excellence Framework is a performance excellence model developed by the U.S. Department of Commerce. It provides a framework for assessing and improving organizational performance in multiple areas, including leadership, strategy, customer focus, measurement and analysis, workforce engagement, operations, and results. The framework emphasizes a systems approach and continuous improvement.

It's important to note that organizations may choose to adopt and tailor these TQM systems or frameworks based on their specific needs and industry requirements. The selection of a TQM system depends on factors such as organizational goals, industry standards, regulatory compliance, and customer expectations.

Steps to Implementing a Total Quality Management System

Implementing a Total Quality Management (TQM) system requires careful planning and execution. While the specific steps may vary depending on the organization and its unique context, here is a general framework that can guide the implementation process:

-

Commitment from Top Management: Obtain commitment and support from top management to drive the implementation of TQM. They should communicate the importance of quality and set clear quality objectives for the organization.

-

Establish a Cross-Functional Team: Form a cross-functional team consisting of representatives from different departments or areas within the organization. This team will be responsible for coordinating and overseeing the TQM implementation process.

-

Assess Current State: Conduct a thorough assessment of the organization's current quality management practices, processes, and systems. Identify strengths, weaknesses, and areas for improvement.

-

Define Quality Policy and Objectives: Develop a quality policy statement that reflects the organization's commitment to quality. Set measurable quality objectives aligned with the organization's strategic goals.

-

Develop a TQM Plan: Create a detailed plan outlining the steps, activities, and timeline for implementing TQM. Define roles and responsibilities, allocate necessary resources, and establish key performance indicators to track progress.

-

Training and Awareness: Provide training and awareness programs to employees at all levels about TQM principles, practices, and their role in implementing and sustaining quality initiatives. This ensures that everyone understands the importance of quality and their contribution to its success.

-

Establish Quality Metrics and Measurement Systems: Identify appropriate quality metrics and establish measurement systems to monitor and evaluate the organization's performance against the defined quality objectives. This includes collecting relevant data, analyzing it, and using it to drive decision-making and improvement efforts.

-

Foster Employee Involvement: Encourage and empower employees to actively participate in quality improvement initiatives. Establish mechanisms for capturing and implementing their suggestions, ideas, and feedback. Create cross-functional teams or quality circles to facilitate collaboration and problem-solving.

-

Continuous Improvement Processes: Implement processes for continuous improvements, such as regular quality audits, management reviews, and corrective action systems. Continuously monitor and analyze data, identify areas for improvement, and implement appropriate actions to enhance quality and address any issues or non-conformities.

-

Supplier Management: Establish effective supplier management processes, including supplier selection, evaluation, and collaboration. Ensure that suppliers adhere to quality standards and work closely with them to achieve mutual quality goals.

-

Communicate and Celebrate Achievements: Regularly communicate the progress, successes, and challenges of TQM implementation to all stakeholders. Celebrate achievements, recognize employee contributions, and create a culture of continuous learning and improvement.

-

Review and Adapt: Conduct periodic reviews of the TQM system to assess its effectiveness and identify areas for refinement. Adapt the system as needed to align with changing organizational needs, industry standards, and customer expectations.

Remember, implementing TQM is an ongoing process that requires continuous commitment, monitoring, and improvement. It is essential to foster a culture that values quality, encourages employee involvement, and embraces the principles of TQM for long-term success.

CONCLUSION

In a world where businesses strive to outshine their competition and meet the ever-increasing demands of customers, Total Quality Management (TQM) emerges as a guiding light, illuminating the path to unrivaled growth and success. Embracing Total Quality Management is a game-changer for organizations aspiring to thrive in today's competitive landscape. By putting customers first, empowering employees, fostering continuous improvement, and nurturing strategic partnerships, TQM paves the way for organizations to surpass their goals, outshine their competitors, and cement their position as industry leaders. So, embark on the TQM journey, embrace continuous improvement, and witness the transformation that awaits your organization. Quality will become ingrained in your DNA, setting you apart from the competition and propelling you towards sustained success. It's time to unleash the power of TQM and drive your organization to new heights.

QUESTION:

What are your thoughts on the subject above? Feel free to post a comment or start a discussion.

TAGS: Total Quality Management, TQM, Excellence, Long-term success, Competitive business landscape, Customer-centric culture, Empowering employees, Continuous improvement, Strong relationships with suppliers, Operational excellence, Customer satisfaction, Reputable brand image, Sustainable growth, Prosperity, Ever-evolving business landscape, Changing customer demands, Relentless competition, Voice of the customer, Exceeding expectations, Process improvement, Waste elimination, Operational efficiency, Streamlined workflows, Resource utilization, Cost reduction, Collaboration, Engagement, Employee involvement, Morale boost, Positive work environment, Implementation challenges, Top management support, Effective communication, Comprehensive training, Measurement systems, Progress tracking, Data-driven decisions, Strategy adaptation, Patience, Perseverance, Continuous learning, Organizational excellence, Game-changer, Thriving in competition, Customer priority, Strategic partnerships, Exceeding goals, Industry leaders, Transformation, Unparalleled achievements.

Leave A Comment